When you’ve gone through each of these steps, click OK.

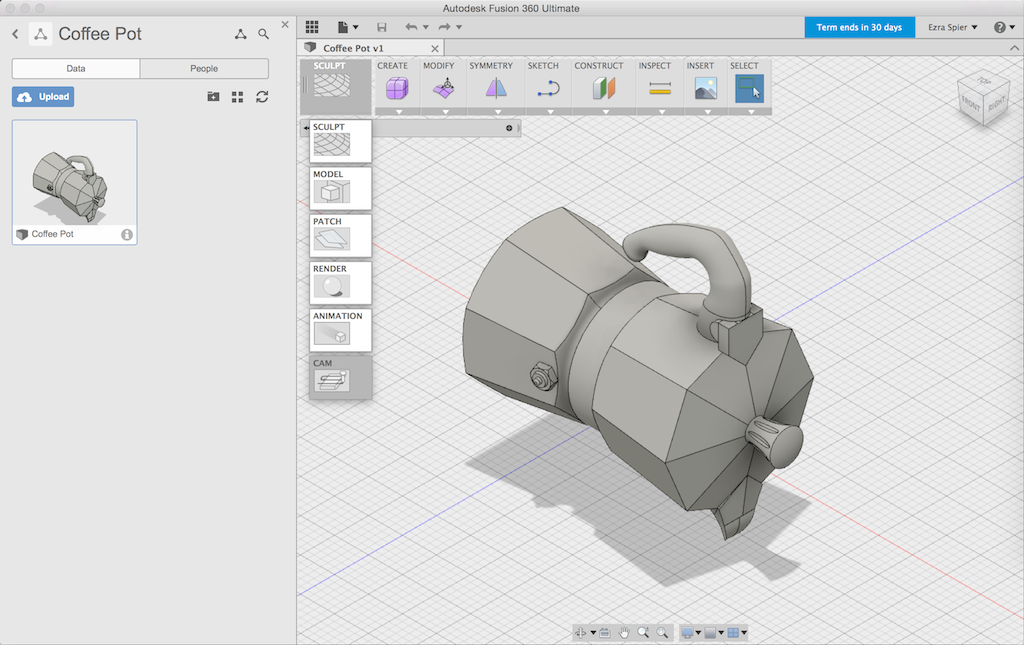

FUSION 360 CAD CAM CNC SOFTWARE

By default, the Bantam Tools software assumes that this point is on the front, left, top corner of the material. To set up a work coordinate system (WCS), you’ll configure the position of the X, Y, and Z axes to match those on your desktop CNC machine. WCS: Specify the coordinate system that the toolpaths will use to machine your design. This will make the bottom of your stock and model the same. For example, in the Stock tab, click Model Position under Height, select Offset from Bottom, and enter 0”. You’ll want to orient the model within the stock to optimize your mill job and your fixturing strategy. Depending on the size of your stock and the CAM strategies you wish to use, you may want to align your model to the surface of your stock or offset it by some absolute amount. Model orientation: By default, Fusion 360 will place your model in the exact center of your stock. Naturally, the less material that needs to be cleared, the more efficient your toolpaths will be. When choosing the size of your stock, think about how much material will be cut away to machine your model. Measure your stock using digital calipers and enter the dimensions of your stock by entering exact values into the Width (X), Depth (Y), and Height (Z) boxes. This will allow you to adjust the dimensions of the stock. Stock size: Click the Stock tab and make sure that “Fixed size box” is selected for the Mode.

The Stock tab sets up the dimensions of the piece of material (or “stock”) you’ll be milling. The Model tab sets the work coordinate system (WCS) for your model. A small panel will open three tabs: Model, Stock, and Post Process. Step 2: Create a new setup.īegin by clicking the Setup menu in the toolbar and select New Setup.

FUSION 360 CAD CAM CNC TRIAL

Note: You can download a free trial of Fusion 360for professional use or the free version for personal use. In the Manage tab, scroll down to Template Library > My Templates > Local and click on the basic CAM templates. When you’re finished designing your CAD, click over to the Manufacturing workspace. Launch Fusion 360 and design your model in the Design workspace. Step 1: Import the Bantam Tools Fusion 360 templates.ĭownload the Basic Bantam Tools Fusion 360 CAM Templates.

Immerse2learn online training solutions are used to develop a skilled workforce in the fields of engineering, manufacturing and automation. Learning content is developed by industry experts and technology providers to ensure the most relevant information and assessments to address the skills needed to be productive in today’s competitive workforce. Learning solutions are available for companies, educators and individuals. VisitÂ. If you’ve ever driven a high-performance car, admired a towering skyscraper, used a smartphone or watched a great film, chances are you’ve experienced what millions of Autodesk customers are doing with our software.

The course includes Engraving, 3D Sign, Micro Wallet, Cell Phone Case, Device Stand, CO 2 Car and Capstone Project.Įducators and students register at Autodesk Fusion 360 Online Course to receive the free online course.Īutodesk is a leader in 3D design, engineering and entertainment software. Autodesk makes software for people who make things. Alignment to Fusion 360 Certified User Objectives and National Institute for Metalworking Skills (NIMS) Standards.CAD for Manufacturing, CAM programming, CNC and First Article Inspection.

The Autodesk Fusion 360 TM Integrated CAD/CAM/CNC for Digital Manufacturing online course provides integrated, project-based curriculum from which the students will learn the following: West Bloomfield, MI – Autodesk and Immerse2learn have partnered to deliver the first online Digital Manufacturing Course that integrates CAD/CAM/CNC & Inspection. And the best part is the online course and Autodesk Fusion 360 software are free!

0 kommentar(er)

0 kommentar(er)